自動焊接設(shè)備的分類及組合

來源:http://m.ykwanda.com/ 發(fā)布時間:2021-11-19 瀏覽次數(shù):0

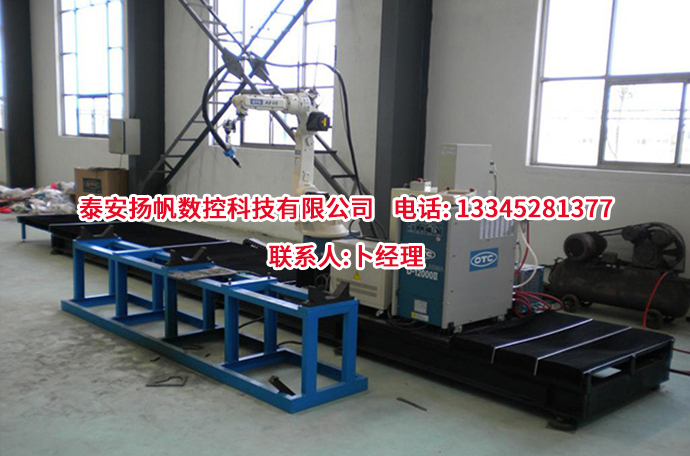

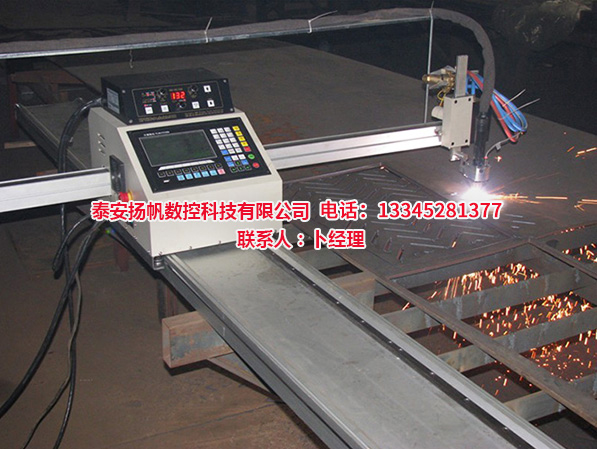

剛性焊接設(shè)備

Rigid welding equipment

也可稱為初級自動化設(shè)備,大部分是根據(jù)開環(huán)控制原理設(shè)計的。雖然設(shè)備自動完成整個焊接過程,但無法對整個過程中參數(shù)的波動進行閉環(huán)反饋控制,也無法隨機修正可能出現(xiàn)的偏差。

Also known as primary automation equipment, most of them are designed according to the open-loop control principle. Although the equipment automatically completes the whole welding process, it can not carry out closed-loop feedback control for the fluctuation of parameters in the whole process, nor can it randomly correct the possible deviation.

2自適應(yīng)控制自動化焊接設(shè)備

2 adaptive control automatic welding equipment

是一種自動化程度高的焊接設(shè)備,裝有電子傳感電路和傳感器,自動引導(dǎo)和跟蹤焊縫軌跡,對主要參數(shù)實行閉環(huán)反饋控制。整個焊接過程將按照預(yù)設(shè)的程序和工藝參數(shù)自動完成。

It is a welding equipment with high degree of automation. It is equipped with electronic sensing circuit and sensor to automatically guide and track the weld track and implement closed-loop feedback control for main parameters. The whole welding process will be completed automatically according to the preset procedures and process parameters.

3智能化自動焊接設(shè)備

3 intelligent automatic welding equipment

它采用多種檢測元件,如視覺傳感器觸摸傳感器聽覺傳感器和激光掃描儀等,并借助計算機軟件系統(tǒng)數(shù)據(jù)庫和系統(tǒng)進行實時識別判斷檢測計算自動編程。焊接參數(shù)的存儲和自動生成焊接日志文件的功能。

It uses a variety of detection elements, such as visual sensor, touch sensor, auditory sensor and laser scanner, and carries out real-time identification, judgment, detection, calculation and automatic programming with the help of computer software system database and expert system. Storage of welding parameters and automatic generation of welding log files.

自動焊接設(shè)備的組成:

Composition of automatic welding equipment:

1焊接電源其輸出功率焊接特性需要與建議的工藝方法相匹配,并配有連接到主控制器的接口。

1. The output power and welding characteristics of the welding power supply shall match the recommended process method, and shall be equipped with an interface connected to the main controller.

2送絲機及其調(diào)速控制系統(tǒng)對于送絲機速度控制精度要求較高的送絲機,控制電路需要加速度反饋。

2 wire feeder and its speed regulation control system for wire feeder with high speed control accuracy, the control circuit needs acceleration feedback.

3焊頭。其運動機構(gòu)由焊頭焊頭支撐架懸掛小車等組成,低于焊頭機構(gòu),其驅(qū)動系統(tǒng)需要采用帶編碼器的伺服電機。

3 welding head. Its motion mechanism is composed of welding head, welding head support frame, suspension trolley, etc., which is lower than the welding head mechanism, and its driving system needs to adopt servo motor with encoder.

4行走機構(gòu),如焊輥架頭尾架翻轉(zhuǎn)機轉(zhuǎn)臺變位機等,活動行走機構(gòu)需要由伺服電機驅(qū)動。

4 traveling mechanism, such as welding roller frame, head and tail frame turnover machine, turntable positioner, etc. the movable traveling mechanism needs to be driven by servo motor.

5主控制器,又稱系統(tǒng)控制器,主要用于自動焊接設(shè)備各部件的鏈接控制,焊接程序的控制,焊接和擴展主要參數(shù)的設(shè)置調(diào)整和顯示故障診斷和人機對話等控制功能。

5 main controller, also known as system controller, is mainly used for link control of various components of automatic welding equipment, control of welding program, setting, adjustment and display of main parameters of welding and expansion, fault diagnosis, man-machine dialogue and other control functions.

6計算機軟件。設(shè)備中常用的軟件有編程軟件功能軟件系統(tǒng)和工藝方法軟件等。

6 computer software. The software commonly used in the equipment includes programming software, function software, expert system and process method software.

7送絲系統(tǒng)循環(huán)水冷卻系統(tǒng)流量回收輸送裝置焊絲架拖鏈及電纜軟管機構(gòu)結(jié)構(gòu)設(shè)計三部分電控設(shè)計等輔助裝置。

7 wire feeding system circulating water cooling system flow recovery conveyor wire rack drag chain and cable hose mechanism structure design three parts electric control design and other auxiliary devices.

8焊頭跟蹤或?qū)驒C構(gòu)弧壓自動控制器焊槍偏航及監(jiān)控系統(tǒng)。

8 welding head tracking or guiding mechanism arc voltage automatic controller welding gun yaw and monitoring system.